How to Identify Potential Issues

Electric motors are vital components in a wide range of industrial and commercial applications, powering machinery and equipment essential for daily operations. As the workhorses of many industries, electric motors require regular maintenance and servicing to ensure optimal performance and prevent costly breakdowns. By being vigilant and attuned to the signs indicating that your electric motor may need servicing, you can address potential issues early and avoid major disruptions to your operations. In this guide, we will explore the top signs that your electric motor requires servicing and how to identify these potential issues.

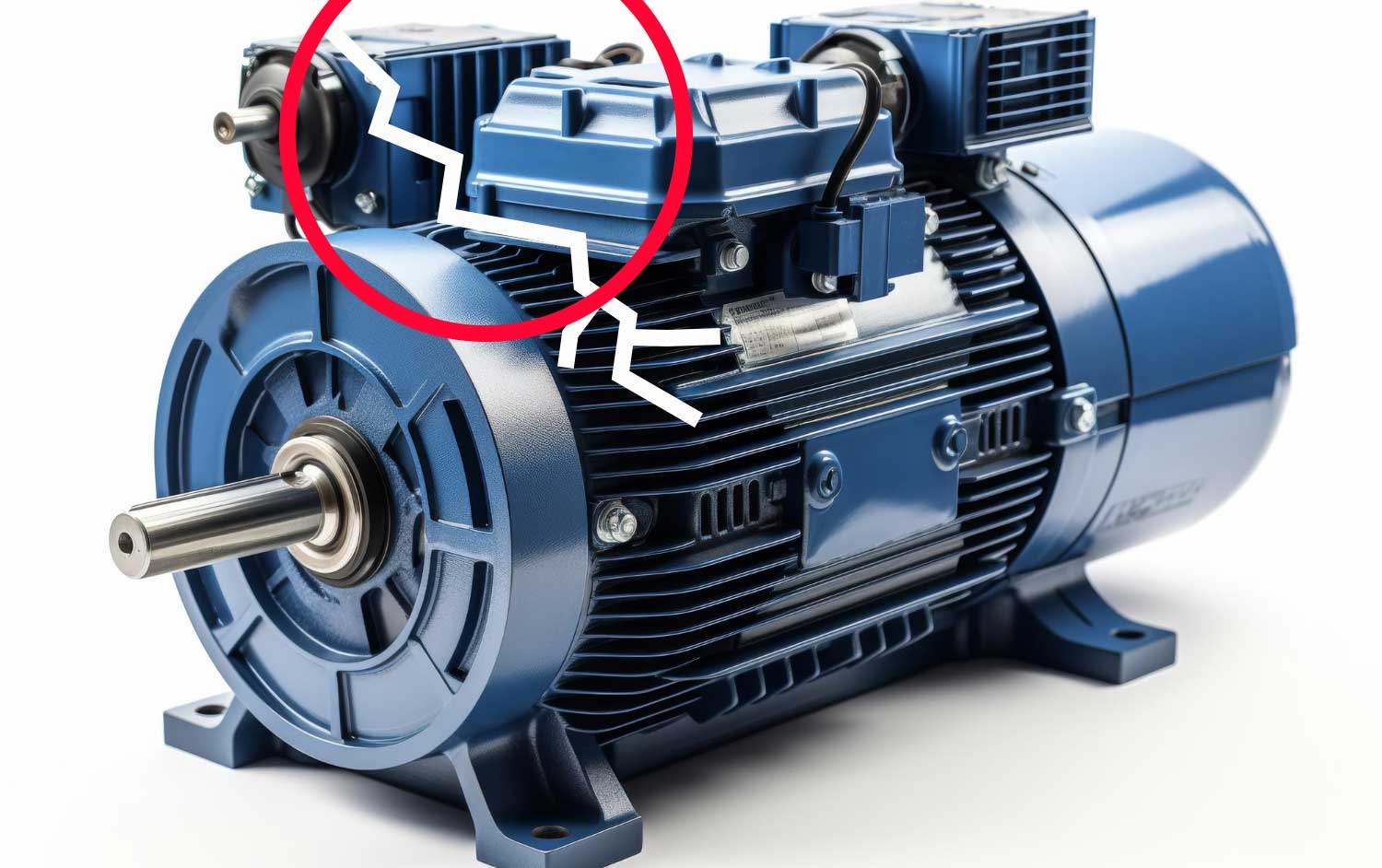

1. Unusual Noise or Vibrations

Unusual noises or vibrations emanating from an electric motor can be early indicators of underlying issues that require attention. Listen for any grinding, humming, or rattling sounds that deviate from the motor’s normal operating noise. Excessive vibration can also signify misalignment, bearing wear, or other mechanical problems. Addressing these unusual noises and vibrations promptly can help prevent more significant damage to the motor.

2. Overheating

Excessive heat buildup in an electric motor can be a red flag signaling potential issues with the motor’s components or insulation. Monitor the temperature of the motor during operation and check for signs of overheating, such as hot spots, burning smells, or discolored insulation. Overheating can lead to insulation breakdown, winding damage, and other internal issues. Prompt servicing can help prevent motor failure and extend its lifespan.

3. Decreased Efficiency and Performance

If you notice a decrease in the efficiency or performance of your electric motor, such as slower operation, stalling, or lack of power, it could indicate underlying problems that need to be addressed. Reduced efficiency may be due to worn components, inadequate lubrication, or electrical issues affecting motor performance. Regular testing and monitoring of the motor’s performance can help identify these issues early on.

4. Excessive Energy Consumption

An electric motor that is consuming more energy than usual may be experiencing efficiency problems or mechanical issues that require servicing. Monitoring the motor’s energy consumption and comparing it to previous benchmarks can help identify abnormal energy usage patterns. Excessive energy consumption not only indicates potential motor issues but also leads to higher operating costs.

5. Frequent Tripping of Circuit Breakers

If your electric motor is causing circuit breakers to trip frequently, it could be a sign of electrical issues, motor overload, or internal faults. Tripped circuit breakers are a safety mechanism designed to protect the motor and electrical system from damage. Investigating the root cause of circuit breaker tripping and addressing the underlying issues promptly can prevent damage to the motor and ensure safe operation.

6. Presence of Smoke or Odors

The presence of smoke, burning smells, or unusual odors coming from an electric motor is a clear indication that servicing is needed. These signs can signify overheating, insulation breakdown, or electrical faults within the motor. Immediate action should be taken to investigate and rectify the source of these warning signs to prevent potential motor failure or safety hazards.

7. Age and Maintenance History

Lastly, the age of the electric motor and its maintenance history are important factors to consider when determining if servicing is necessary. Older motors may require more frequent maintenance to ensure continued reliability and performance. Additionally, adherence to regular maintenance schedules and keeping detailed records can help identify when servicing is due based on manufacturer recommendations.

Hopefully the above list makes it clear that being proactive in identifying the signs that your electric motor needs servicing is essential for maintaining the reliability and efficiency of your equipment. By monitoring for unusual noises, vibrations, overheating, decreased performance, excessive energy consumption, circuit breaker tripping, and unusual smells, you can address potential issues early and prevent costly downtime. Regular maintenance and servicing of electric motors are key to maximizing their lifespan, optimizing performance, and ensuring uninterrupted operations in your industrial or commercial settings. By staying vigilant and attentive to these signs, you can proactively address motor issues and keep your operations running smoothly.

When it comes to electric motor advice, servicing, support and parts, you can’t go past National Electric Motor Services in Western Australia. https://nems.com.au/